- +44 (0)1953 454540 enquiries@stuartwells.co.uk

Loading ...

Client: EKFB JV

Location: Wendover, Buckinghamshire

Duration: November - December 2020

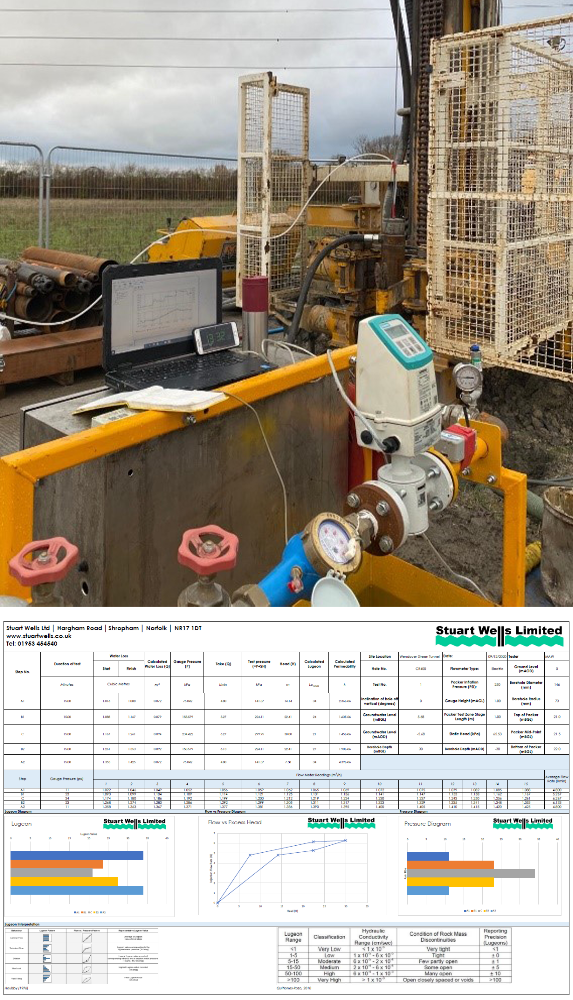

Stuart Wells were employed as a subcontractor to undertake a series of packer tests in accordance with BS EN ISO 22282-3:2012, geophysical logging and a series of pumping tests in accordance with BS ISO 14686:2003, as part of ground investigation works in Wendover, Buckinghamshire.

As part of the works two pumping wells and one monitoring well were drilled using in 146mm Geobore S, the two pumping wells were packer tested.

After drilling, the open borehole was flushed by the drilling contractor. We also undertook substantial open hole airlift development as the well was drilled in the West Melbury Marly Chalk and Zig Zag Chalk Formation.

Geophysical logging and subsequent data interpretation was undertaken by Stuart Wells to establish fracture zones and suggested packer testing zones and pressures. Once determined Geobore S was re-installed and a wireline Geopro ‘double’ packer testing system was installed. Packer testing was undertaken using 3 packers lowered into the borehole on the drilling rigs winch. One was inflated within the Geobore S to maintain the integrity of the test, then two inflated below the casing with a 1m testing zone between them, these were inflated utilising inert Nitrogen gas. As part of this method of packer testing it utilised the Geobore S as the riser and pressurises the borehole as such.

Each individual packer test comprised of ‘5no steps’, 25%, 50%, 75%, 50% and 25% of calculated rock mass, Stuart Wells conducted this testing in accordance with BS EN ISO 22282-3:2012. These steps were undertaken for 15 minutes each and repeated in each defined testing zone, we are able to measure pressure in 3 zones within the borehole utilising 3 pressure transducers and 1 barometric datalogger. Testing was undertaken from the bottom to the top of the borehole. The maximum injected water rate was 2.5 l/s. This testing was undertaken in both boreholes and 13 no. tests were undertaken in total. A full factual report was produced and submitted to the client with calculated permeability (k) m/s provided.

Copyright © 2024 Stuart Wells Limited, all rights reserved.