Stuart Wells have the equipment, resources and experience to undertake a variety of on-site Packer Testing Systems in accordance to BS EN ISO 22282-3.

Single Packer Hydraulic Conductivity Testing

Single Packer Hydraulic Conductivity Testing

A single packer is installed on a wireline system into 146mm Geobore S casing and installed to the required testing depth. Whereby the casing is pressurised to the required levels and the packer testing is undertaken. This form of Packer Testing can be undertaken at stages as drilling and coring progresses.

Double Packer’ Hydraulic Conductivity Testing

The, ‘double packer’ system is undertaken with 3 inflated packers, whereby one packer is inflated within the 146mm Geobore S casing, one underneath the casing shoe and another at the bottom of the clients requested test section. This method of hydraulic conductivity testing can be undertaken after the borehole is complete or whilst drilling to allow for absolute flexibility in any hydraulic conductivity testing requirements.

Pump-Out’ Packer Testing

To enable ‘pumping tests’ to be undertaken with in distinctive zones of a borehole. A 415V submersible borehole pump (flow range 0.1 – 4.5 l/s) can be attached to the bottom of a single or within a double packer system. With inflated packers this isolates the testing zone where a short abstraction or pumping test can be undertaken. This method is subject to assessment, depending on rock conditions, in particular the risk of generating fines and damaging the pump. This method of packer testing can also be used for attaining groundwater samples from specific horizons.

Riser-less Borehole Installation with Permanent Packers

Riser-less Borehole Installation with Permanent Packers

A packer is used to isolate a specific pumping zone within a well, with a submersible attached and located to the bottom of a single or within a double packer system. Abstracted water passes through the packer with the overlaying cased section of the borehole acting as the riser to a flanged wellhead and flow control arrangement at the top of the well.

Our Packer Specifications:

- Either 1 or 3 packers are utilised, depending on testing methods required.

- Inflation is possible with either neutral gas or water.

- High water injection rates attainable.

- Any test zone length required. As standard 1m and 2m are often utilised.

- 3 x Downhole Pressure Transducers and Barometric at Surface.

- 1 x Live Downhole Pressure Transducer.

- 2 x Flowmeters. A propellor and electric Flowmeter with Telemetry Datalogger.

- 2 x Pressure Gauges. Bouyon pressure gauge and auto-logging electric datalogger pressure gauge.

Reporting

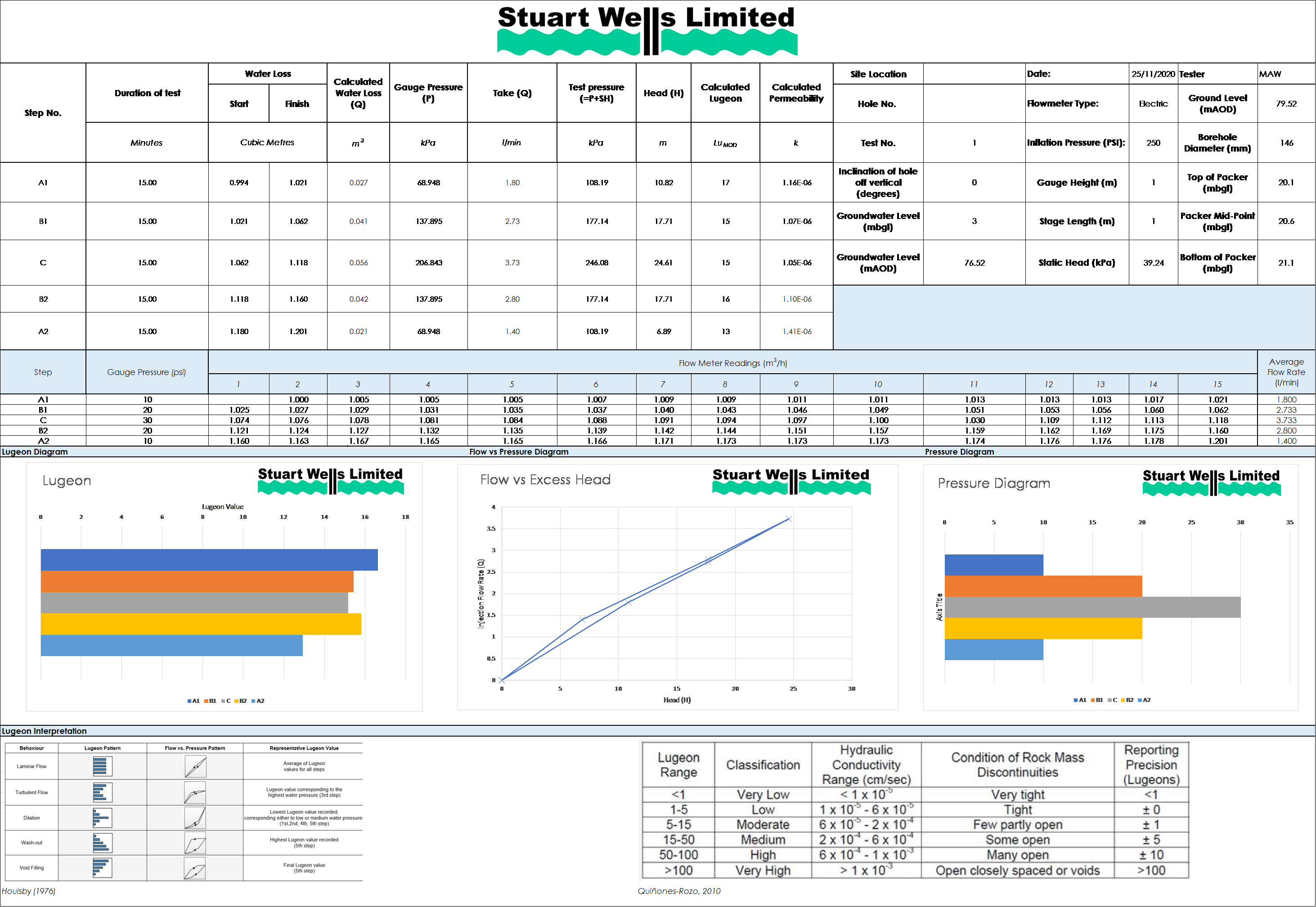

Upon completion we issue a factual report on works undertaken which includes permeability assessments on each packer test.